Get a data-driven overview of the oral liquid CDMO market, including size, key growth drivers, major trends, and future forecasts to inform your strategy. As the pharmaceutical landscape evolves, understanding the dynamics of specialized manufacturing partners is more crucial than ever.

State of the Oral Liquid CDMO Market: Key Takeaways for 2026

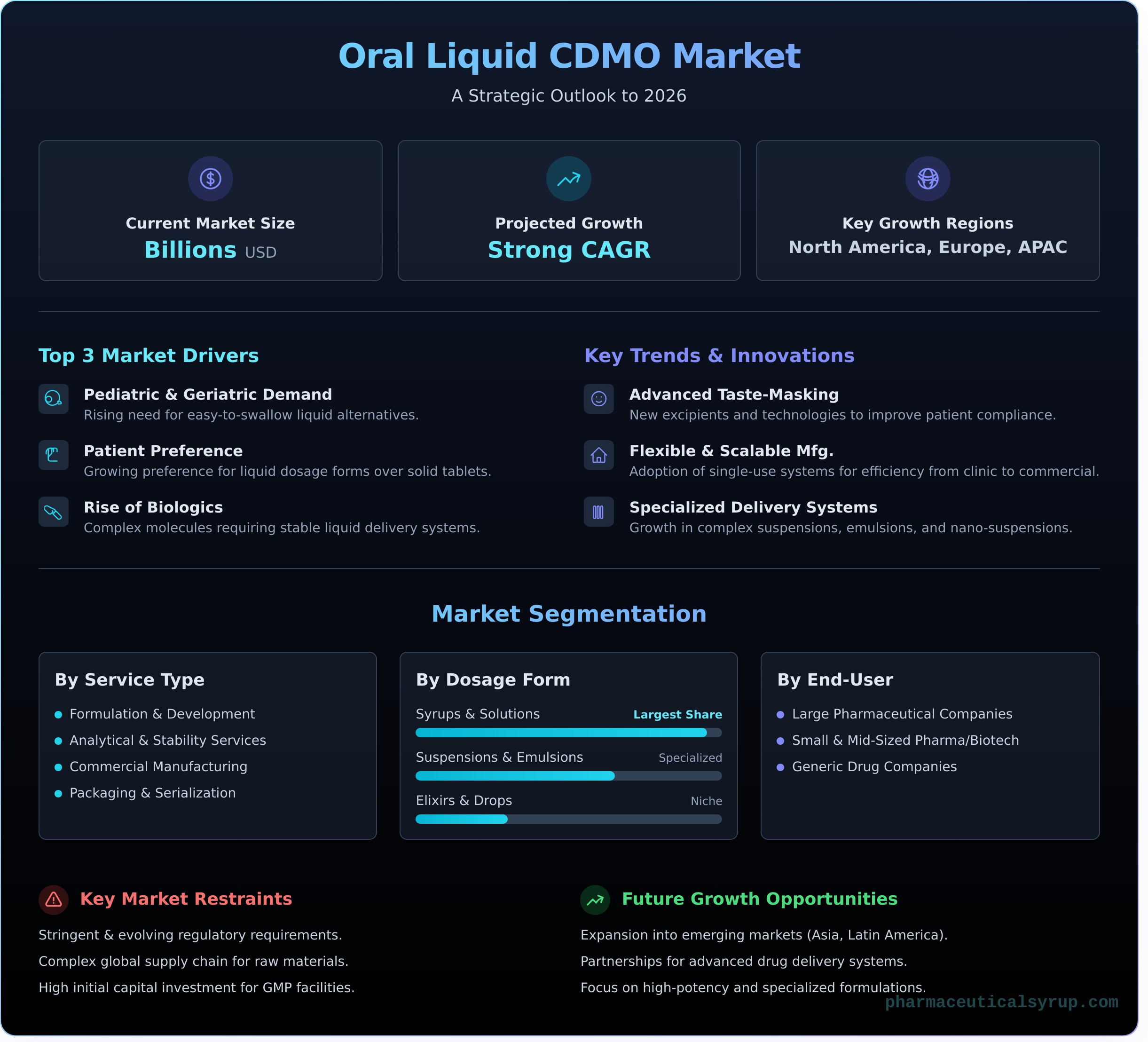

In a concise summary box for those needing the key facts quickly: the oral liquid CDMO market is experiencing robust expansion, driven by patient-centric drug development and advancements in formulation science. An oral liquid Contract Development and Manufacturing Organization (CDMO) is a specialized partner that provides comprehensive services to pharmaceutical companies, from initial formulation and development to large-scale commercial manufacturing of liquid dosage forms like syrups, suspensions, and solutions. This market’s role has become increasingly critical as companies seek to outsource complex manufacturing processes to focus on core R&D and marketing, while also leveraging the specialized expertise of CDMOs to bring better products to market faster.

Current Market Size and Future Projections

According to recent industry analysis, the current global market value for oral liquid CDMOs is estimated in the billions of USD. Projections indicate a strong and sustained compound annual growth rate (CAGR) over the next five years, signaling significant confidence and investment in this sector. Key regions fueling this expansion include North America, with its advanced pharmaceutical industry, followed closely by Europe and a rapidly growing Asia-Pacific (APAC) market, where demand for accessible and easy-to-administer medications is on the rise.

Top 3 Market Drivers Fueling Growth

Several key factors are propelling the oral liquid CDMO market forward. First, there is a rising demand for pediatric and geriatric formulations. These patient populations often have difficulty swallowing solid pills, making effective, palatable liquid alternatives essential for treatment adherence. Second, a broader patient preference for liquid dosage forms over traditional tablets and capsules is pushing drug developers to reformulate existing products and prioritize liquids for new ones. Finally, the significant growth in biologics and other complex molecules, many of which are not stable in solid form, necessitates liquid delivery systems, further expanding the need for specialized CDMO partners.

Key Trends and Innovations Shaping the Future

The oral liquid manufacturing space is undergoing major shifts driven by new technologies, evolving patient needs, and changing regulatory expectations. Staying ahead of these trends is vital for both pharmaceutical companies and the CDMOs that serve them.

Advanced Formulation and Taste-Masking Technologies

Patient compliance is directly linked to the palatability of a medication, especially in chronic and pediatric therapies. Consequently, advanced taste-masking has become a cornerstone of innovation. CDMOs are leveraging new, functional excipients and sophisticated technologies like microencapsulation and ion-exchange resins to effectively hide the bitter taste of many active pharmaceutical ingredients (APIs). A CDMO with proven expertise in this area offers a distinct competitive advantage, turning a challenging formulation into a successful, patient-friendly product.

Flexible Manufacturing and Scale-Up Capabilities

The modern drug development pipeline demands flexibility. There is a growing demand for CDMOs that can seamlessly manage projects from early clinical trial batches to full commercial scale production. The adoption of single-use systems and modular manufacturing suites is a key trend, allowing for faster changeovers, reduced cross-contamination risk, and greater cost-efficiency. A CDMO’s ability to execute a smooth and predictable tech transfer process is a critical factor for clients looking to avoid costly delays on the path to market.

Focus on Specialized Drug Delivery Systems

Beyond simple solutions and syrups, the market is seeing a growth in demand for more complex drug delivery systems. Formulations like suspensions, emulsions, and advanced nano-suspensions are crucial for delivering poorly soluble APIs, improving bioavailability, and ensuring dose uniformity and stability. To meet this need, leading CDMOs are making significant investments in specialized equipment for high-shear mixing, homogenization, and particle size reduction, positioning themselves as partners for the most challenging formulation projects.

Oral Liquid CDMO Market Segmentation: A Closer Look

To fully understand the market, it’s helpful to break it down into its core components. The following segments illustrate the diverse services and products that define the oral liquid CDMO landscape.

Analysis by Service Type

- Formulation & Development: This is the critical first step where the drug product is designed, including API characterization, excipient selection, and prototype development.

- Analytical Services & Stability Testing: These services ensure the product is safe, effective, and stable throughout its shelf life, meeting all regulatory requirements.

- Commercial Manufacturing & Scale-Up: This involves taking a validated formula and producing it at a large scale under strict Good Manufacturing Practice (GMP) conditions.

- Packaging, Labeling, and Serialization: The final step includes primary and secondary packaging, as well as implementing track-and-trace serialization to secure the supply chain.

Analysis by Dosage Form

- Syrups & Solutions: Representing the largest market share, these are homogenous mixtures that are easy to manufacture and administer.

- Suspensions & Emulsions: These are essential for delivering insoluble or poorly soluble APIs, requiring specialized formulation and manufacturing expertise.

- Elixirs and Drops: These are often used for potent drugs requiring precise, low-volume dosing, representing a niche but important market segment.

Analysis by End-User

- Large Pharmaceutical Companies: Often outsource legacy products or specialized liquid formulations to optimize their internal manufacturing capacity.

- Small and Mid-Sized Pharma & Biotech: Frequently rely on CDMOs as their primary manufacturing arm, lacking the internal infrastructure for large-scale production.

- Generic Drug Companies: Partner with CDMOs for cost-effective manufacturing of off-patent liquid medications.

Navigating Challenges and Seizing Opportunities

Like any dynamic market, the oral liquid CDMO sector presents both potential hurdles and significant rewards. Successful companies will be those that can adeptly navigate the challenges while strategically capitalizing on emerging opportunities.

Key Market Restraints

Companies operating in this space face several challenges. Stringent and constantly evolving regulatory requirements from bodies like the FDA and EMA demand continuous investment in compliance and quality systems. Furthermore, the complexities of the global supply chain for high-quality raw materials and excipients can introduce risk and volatility. Finally, the high initial capital investment required to build and maintain GMP-compliant facilities creates a significant barrier to entry.

Future Growth Opportunities

Despite the challenges, the opportunities for growth are substantial. Expansion into emerging markets across Asia and Latin America, where healthcare infrastructure and patient demand are rising, presents a major opportunity. There is also significant potential in the development of liquid formulations for orphan drugs targeting rare diseases, which often affect pediatric populations. Finally, forming strategic partnerships with innovative biotech startups to help bring their novel molecules from the lab to the clinic is a key avenue for growth. Let’s discuss how to turn these opportunities into reality for your project.

Frequently Asked Questions

What is the projected size of the oral liquid CDMO market by 2030?

Based on current growth rates, industry analysts project the market will continue its strong upward trajectory, reaching a significantly higher valuation by 2030, driven by the factors discussed in this article.

Who are the major players in the oral liquid CDMO market?

The market includes a mix of large, multinational CDMOs with diverse capabilities and smaller, specialized firms that focus exclusively on liquid dosage forms. Key players are often distinguished by their regulatory track record, technological capabilities, and experience with specific formulations like suspensions or high-potency compounds.

Which region is expected to show the fastest growth in this market?

The Asia-Pacific (APAC) region is widely expected to exhibit the fastest growth rate due to increasing healthcare expenditure, a growing generics market, and rising investment from pharmaceutical companies in the region.

What are the main advantages of outsourcing to an oral liquid CDMO?

The primary advantages include access to specialized expertise and technology, reduced capital expenditure, faster speed to market, and the ability for the client company to focus on its core competencies, such as drug discovery and marketing.

How does the trend towards personalized medicine affect the oral liquid market?

Personalized medicine often requires flexible dosing, which is much easier to achieve with liquid formulations than with fixed-dose solid tablets. This trend is expected to further boost demand for CDMOs capable of producing small, customized batches of liquid medicines.

Choosing the right manufacturing partner is a critical decision that impacts your product’s success from development through its entire lifecycle. By partnering with a CDMO that offers end-to-end services, operates FDA and EMA compliant GMP facilities, and has proven expertise in complex pediatric and geriatric formulations, you can de-risk your project and ensure a reliable supply of high-quality medicine for patients. Partner with an expert in oral liquid formulation and manufacturing.