Understanding the end-to-end Good Manufacturing Practice (GMP) syrup manufacturing process is essential for ensuring product safety, efficacy, and regulatory approval. This guide will walk you through the entire workflow, from raw material handling to final product release, providing a clear roadmap for achieving quality and compliance at every stage.

Core Principles of GMP in Syrup Manufacturing

Good Manufacturing Practice (GMP) is the bedrock of pharmaceutical production. It provides a framework of systems and procedures that collectively ensure every batch of a medicinal product is consistently produced and controlled to the quality standards appropriate for its intended use. More than just a best practice, GMP is a legal requirement enforced by regulatory bodies like the FDA and EMA. Its principles apply comprehensively to all aspects of production, including the manufacturing facilities, processing equipment, personnel, and all associated documentation.

The Role of the Quality Management System (QMS)

At the heart of GMP is the Quality Management System (QMS). This formal system defines and documents all procedures, processes, and responsibilities for achieving the company’s quality policies and objectives. For syrup manufacturing, the QMS includes detailed Standard Operating Procedures (SOPs) for every task, comprehensive batch records that capture every production step, and robust change control protocols. A well-implemented QMS guarantees complete traceability, allowing you to track every component from the initial raw materials to the final distributed product.

Personnel Training and Facility Requirements

People and places are critical components of GMP. All staff involved in manufacturing must receive documented, role-specific training to ensure they have the skills and knowledge to perform their duties competently and hygienically. The manufacturing facility itself must be designed, constructed, and maintained to prevent mix-ups and cross-contamination. This involves creating logical process flows, using smooth and easily cleanable surfaces, and implementing strict environmental monitoring and controlled access to production areas.

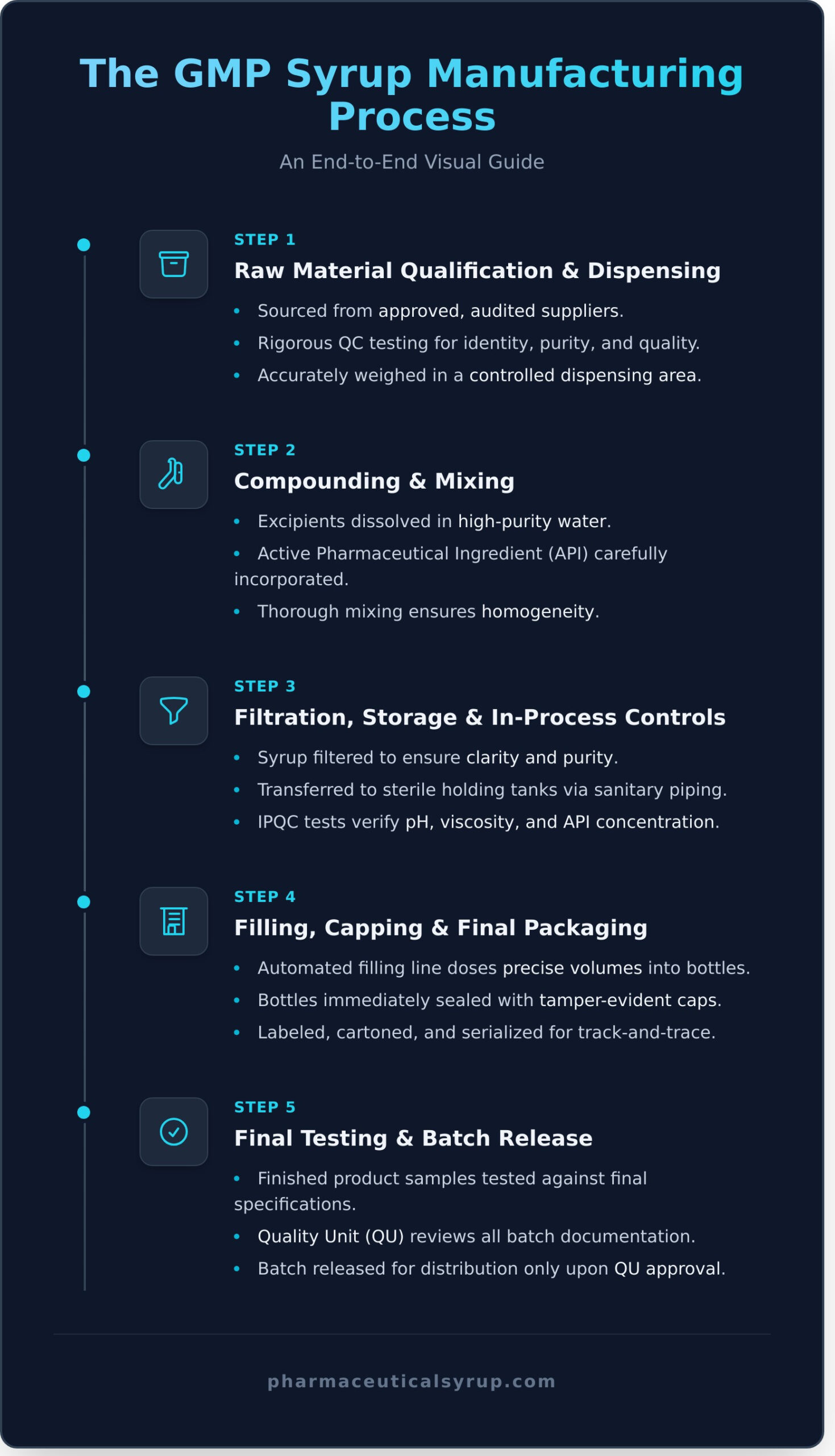

The GMP Syrup Manufacturing Process: A Step-by-Step Breakdown

The manufacturing of pharmaceutical syrup follows a highly controlled and validated process, where each step is meticulously documented in the Batch Manufacturing Record (BMR). This critical document serves as the live record and proof that the batch was produced according to the approved master formula and GMP requirements.

Step 1: Raw Material Qualification and Dispensing

Quality begins with the ingredients. All raw materials, including the Active Pharmaceutical Ingredient (API) and excipients, must be sourced from approved, audited suppliers. Upon receipt, each material undergoes rigorous identity, purity, and quality testing by the Quality Control (QC) department before it can be released for use. Once approved, materials are accurately weighed and documented by trained personnel in a dedicated, environmentally controlled dispensing area to prevent contamination.

Step 2: Compounding and Mixing

The first step in compounding is the preparation of high-purity water, which typically serves as the primary solvent or vehicle in a syrup formulation. In a dedicated, jacketed manufacturing vessel, sugar and other excipients (such as preservatives, buffers, and flavoring agents) are dissolved in the purified water according to the BMR. The Active Pharmaceutical Ingredient (API) is then carefully incorporated into the solution, followed by thorough mixing to ensure complete dissolution and homogeneity.

Step 3: Filtration, Storage, and In-Process Controls

Once the syrup is fully compounded, it is filtered to remove any particulate matter, ensuring product clarity and purity. The bulk syrup is then transferred through sanitary piping to a sterile holding tank, where it awaits the filling process. Throughout compounding and storage, critical In-Process Quality Control (IPQC) tests are performed at specified intervals. These tests typically include measuring pH, viscosity, specific gravity, and performing an assay to confirm the API concentration is within its specified limits.

Step 4: Filling, Capping, and Final Packaging

From the holding tank, the syrup is fed to an automated filling line where precise volumes are dosed into clean primary containers (usually glass or plastic bottles). The bottles are then immediately sealed with caps, often with induction seals to provide tamper-evidence. Finally, the sealed bottles undergo labeling, are placed into cartons with patient information leaflets, and are serialized with unique identifiers to meet global track-and-trace regulations.

Ensuring Ongoing Compliance and Quality

Manufacturing a single successful batch is not enough; GMP demands that quality is consistently maintained over time. This is achieved through robust systems designed to prevent deviations, control processes, and ensure that every product batch meets its predefined specifications and quality attributes.

Process Validation: Proving Your Process Works

Process validation is the documented evidence that proves a manufacturing process, when operated within established parameters, consistently produces a product meeting its predetermined specifications. Before a product can be sold commercially, the process must typically be validated by successfully manufacturing three consecutive production-scale batches. This crucial step demonstrates that the process is robust, reliable, and under control.

Cleaning Validation and Environmental Monitoring

To prevent cross-contamination between different products made using the same equipment, rigorous cleaning procedures must be validated. Cleaning validation provides documented proof that the approved cleaning process effectively removes all product residues to scientifically established limits. Concurrently, an environmental monitoring program regularly tests the air quality and surfaces within the cleanrooms to ensure microbial levels remain within safe, controlled limits.

Final Product Testing and Batch Release

After packaging is complete, representative samples of the finished product are taken for final Quality Control testing. These tests confirm that the syrup meets all its final specifications for identity, strength, quality, and purity. The Quality Unit (QU) performs a comprehensive review of all associated documentation, including the BMR and all QC test results. No batch can be released for sale or distribution without this final, documented approval from the QU.

Partnering with a GMP-Compliant CDMO

Navigating the complexities of GMP manufacturing requires significant expertise and infrastructure. For many companies, partnering with a reliable Contract Development and Manufacturing Organization (CDMO) is the most efficient way to bring a product to market. When selecting a partner, look for a CDMO with a strong regulatory inspection history with agencies like the FDA and EMA. It is critical to ensure they have specific, demonstrable experience with oral liquid dosage forms to avoid costly delays. A good partner acts as an extension of your team, providing the technical and regulatory support needed for success. To learn more about how a partnership can streamline your production, you can Request a consultation on your syrup manufacturing project.

Frequently Asked Questions

What is a Batch Manufacturing Record (BMR)?

A Batch Manufacturing Record is a detailed, step-by-step record of the entire production process for a single batch of product. It includes information on raw materials used, equipment logs, in-process control results, signatures of personnel who performed and verified each step, and any deviations that occurred. It serves as the legal proof that the batch was manufactured in accordance with GMP and the master formula.

Why is water quality so critical in syrup manufacturing?

Water is often the largest component by volume in a syrup, making its quality paramount. It must be free from microbial and chemical contaminants that could degrade the product or harm the patient. Pharmaceutical-grade purified water is produced through processes like reverse osmosis and deionization to meet strict pharmacopeial standards for purity.

What is the difference between aseptic processing and terminal sterilization for syrups?

Aseptic processing involves sterilizing the product and the container/closure system separately and then bringing them together in a sterile environment. Terminal sterilization involves filling the product into its final container and then sterilizing the entire sealed unit, typically using heat. The choice depends on the stability of the API and other ingredients to heat.

How do you prevent microbial contamination during production?

Microbial control is achieved through a multi-faceted approach: using high-quality raw materials with low bioburden, operating in classified cleanrooms with filtered air, following strict gowning and hygiene procedures for personnel, using validated cleaning and sanitization procedures for equipment, and often including preservatives in the formulation itself.

What are the most common GMP deficiencies found in audits?

Common deficiencies cited by regulatory inspectors often relate to inadequate documentation (incomplete batch records), insufficient investigation of deviations or out-of-specification results, poor data integrity practices, and deficiencies in cleaning validation or process validation programs.

Successfully navigating the path of GMP syrup manufacturing requires a deep commitment to quality and a thorough understanding of regulatory expectations. By implementing a robust Quality Management System and partnering with experienced professionals, you can ensure your product is manufactured to the highest standards of safety and efficacy. Our FDA & EMA compliant manufacturing facilities, combined with decades of experience in oral liquid formulations and dedicated project management, are here to support your project from concept to commercialization. Discuss your syrup manufacturing needs with our experts.